Introduction:

The world of industrial pipe fabrication is continually evolving, driven by the need to meet the challenging demands of extreme environments. In high-pressure scenarios and corrosive conditions, traditional pipe fabrication methods often fall short. This article dives into the innovative techniques that are setting new standards in pipe fabrication, offering robust, reliable solutions in the harshest of conditions.

High-Pressure Environments: A Test of Strength and Precision

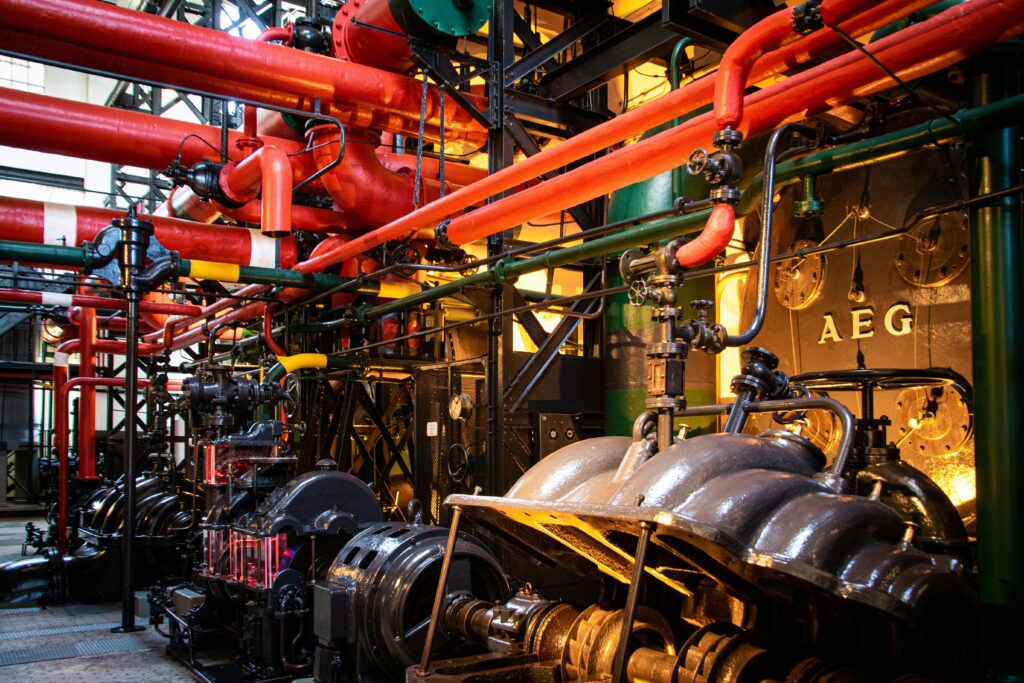

High-pressure environments, common in industries like oil and gas extraction, power generation, and chemical manufacturing, require pipes that can withstand immense internal pressures. Here, the material selection, design, and fabrication methods are critical to ensuring safety and functionality.

- Material Matters:

For high-pressure applications, the choice of material is paramount. Advanced alloys, such as chrome-molybdenum steel, are favored for their exceptional strength and durability. These alloys can withstand high temperatures and pressures, making them ideal for high-stress environments.

- Precision Welding Techniques:

Welding in high-pressure pipe fabrication demands precision and expertise. Techniques like Tungsten Inert Gas (TIG) welding are often employed for their ability to produce strong, high-quality welds. Automated welding technologies are also gaining traction, offering consistent results and reducing human error.

- Stress-Relief Processes:

Post-weld heat treatment (PWHT) is a critical step in high-pressure pipe fabrication. It involves heating the welded material to a specific temperature and then cooling it under controlled conditions. This process relieves residual stresses from welding, enhancing the strength and resilience of the pipes.

Corrosive Environments: Combating Chemical Assault

Corrosive environments pose a different set of challenges. Pipes used in industries such as chemical processing, wastewater treatment, and marine applications often face aggressive chemicals and corrosive substances.

- Corrosion-Resistant Materials:

In these settings, materials like duplex stainless steel and nickel alloys are popular for their corrosion resistance. These materials can endure prolonged exposure to corrosive agents, minimizing maintenance needs and extending the pipe’s lifespan.

- Protective Coatings and Linings:

Beyond material selection, protective coatings and linings play a vital role in combating corrosion. Epoxy, polyurethane, and other specialized coatings are applied to the pipe’s surface, creating a barrier against corrosive elements.

- Advanced Fabrication for Extreme Conditions:

For pipes used in particularly harsh chemical environments, fabrication techniques must ensure that coatings and linings are applied seamlessly, avoiding any weak spots that could be prone to corrosion.

Innovations in Pipe Fabrication: Looking Ahead

The field of pipe fabrication is not static; it’s a realm of constant innovation. Advancements in materials science, welding technology, and fabrication processes continue to push the boundaries of what’s possible. Smart pipes equipped with sensors are on the horizon, promising real-time monitoring of pipe conditions and early detection of potential issues.

Conclusion: Rising to the Challenge of Pipe Fabrication Techniques

As industries continue to venture into more extreme conditions, the need for innovative pipe fabrication techniques that can withstand these demanding environments becomes increasingly crucial. Through a combination of advanced materials, precision engineering, and innovative technologies, the pipe fabrication industry is well-equipped to meet these challenges head-on.

By embracing these cutting-edge techniques, we not only ensure the safety and efficiency of industrial operations but also pave the way for future advancements that will continue to revolutionize the field. Reach out to us at Ansgar to start a conversation.