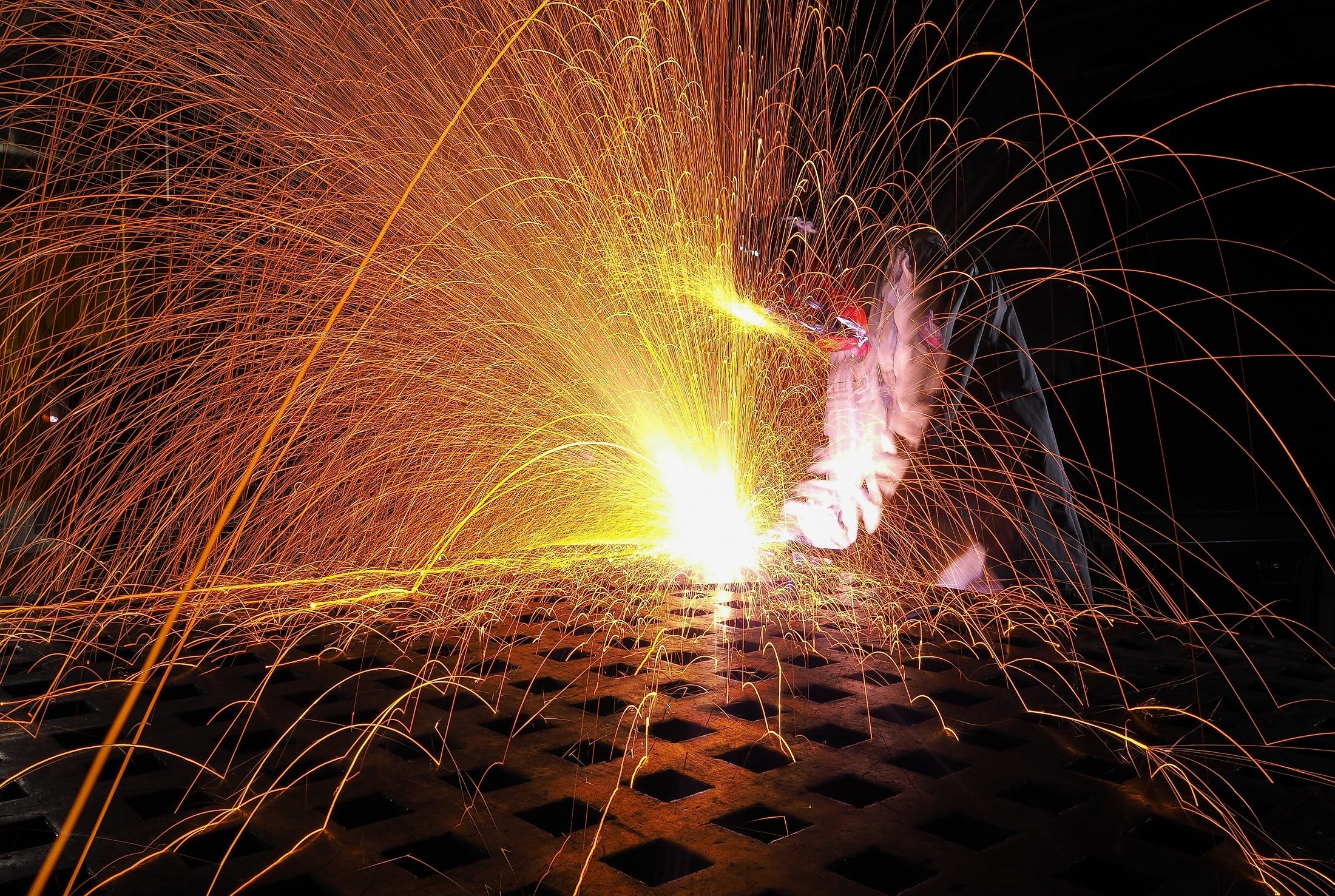

Pipe fabrication is a critical process in various industries such as oil and gas, construction, and manufacturing. Achieving high-quality welds is essential for the integrity and reliability of pipelines. One welding process that has gained popularity in pipe fabrication is Flux-Cored Arc Welding (FCAW). In this blog, we will explore the key aspects of FCAW and how it contributes to efficient and effective pipe fabrication.

Understanding Flux-Cored Arc Welding (FCAW):

Flux-Cored Arc Welding is a semi-automatic or automatic arc welding process that utilizes a tubular electrode filled with flux. The flux not only serves as a shielding agent to protect the weld pool from atmospheric contaminants but also provides essential elements to the molten metal, enhancing the overall quality of the weld.

Advantages of FCAW in Pipe Fabrication:

- High Productivity: FCAW is known for its high deposition rates, making it a productive choice for pipe fabrication. The process allows for faster welding speeds compared to some other welding methods, contributing to increased efficiency in the fabrication process.

- All-Position Welding: One of the significant advantages of FCAW is its suitability for all-position welding. This is particularly beneficial in pipe fabrication, where welding needs to be performed in various orientations. Whether it’s a horizontal, vertical, or overhead position, FCAW provides versatility and ease of use.

- Deep Penetration: FCAW can achieve deep penetration, ensuring strong and durable welds. This is crucial in pipe fabrication, where welding integrity is paramount to withstand the demanding conditions, pipelines may encounter.

- Cost-Effectiveness: The high deposition rates of FCAW contribute to cost savings in terms of labor and material. Faster welding speeds and fewer passes result in reduced overall fabrication time, making it a cost-effective choice for many projects.

Best Practices for FCAW in Pipe Fabrication:

- Proper Joint Preparation:

- Ensure that the pipe joints are adequately prepared before welding. Cleanliness and proper beveling of the edges are crucial for achieving strong and defect-free welds.

- Optimal Voltage and Amperage Settings:

- Fine-tuning the welding parameters, including voltage and amperage, is essential for achieving the desired weld quality. Consult welding procedure specifications (WPS) and adjust settings according to the pipe material and thickness.

- Choosing the Right FCAW Electrode:

- Selecting the appropriate flux-cored electrode is critical for successful pipe fabrication. Consider factors such as the base metal, welding position, and desired mechanical properties when choosing the electrode.

- Maintaining Consistent Travel Speed:

- Consistency in travel speed is essential for uniform weld bead formation. Deviations in travel speed can lead to irregularities and compromise the integrity of the weld.

Conclusion

Flux-Cored Arc Welding has become a preferred choice in pipe fabrication due to its numerous advantages, including high productivity, versatility, and cost-effectiveness. By understanding the key principles and implementing best practices, welders can master FCAW to ensure the production of high-quality welds in pipe fabrication projects. As technology and techniques continue to evolve, FCAW is likely to remain a valuable asset in the arsenal of welding processes for the construction of reliable and robust pipelines.