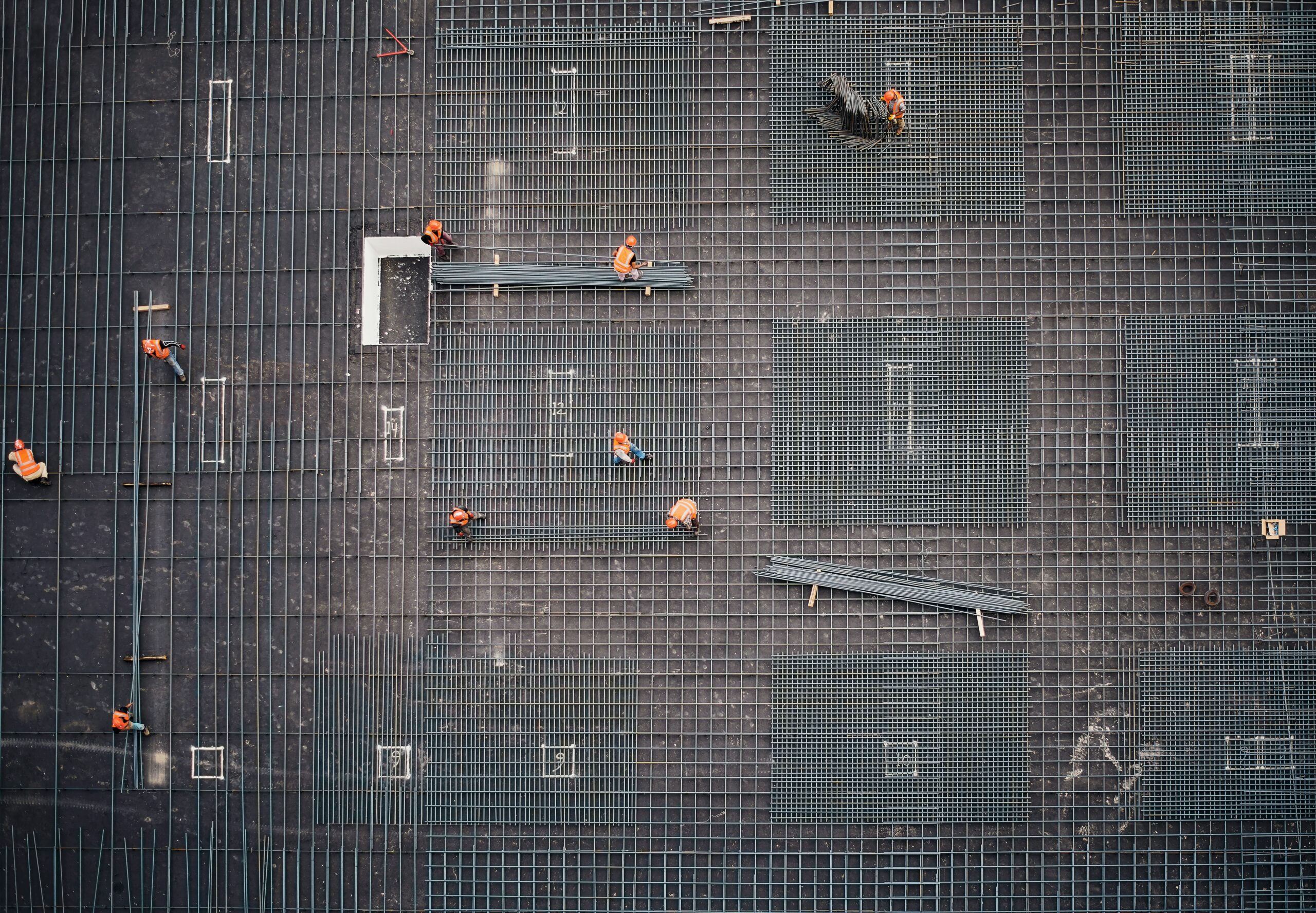

Industrial projects rarely fail because the engineering was wrong. They slip when execution gets fragmented across too many handoffs, when field conditions change faster than the plan, or when coordination breaks down between fabrication, logistics, and installation. That is why owners and EPC teams increasingly look for partners that can deliver a Complete Spectrum of Field Services instead of a narrow slice of labor.

For Ansgar, “field services” is not just sending people to a jobsite. It is the full set of capabilities required to mobilize safely, install correctly, document thoroughly, and close out cleanly. When field execution is supported by a complete, integrated approach, projects move faster, quality is more consistent, and the team spends less time reacting to surprises.

What “Complete Spectrum of Field Services” Really Means

A Complete Spectrum of Field Services covers the work that happens from the moment a crew is mobilized to the day the owner signs final acceptance. It includes the craft labor, supervision, safety leadership, quality control, and project coordination required to deliver scope in real-world site conditions.

In practice, this means the field team can handle:

- Site readiness and mobilization planning

- Installation and tie-ins for piping and mechanical scope

- Support for scheduling, work packaging, and daily coordination

- QA and documentation that match project requirements

- Safety programs that align with jobsite rules and regulatory expectations

- Testing, turnover, and closeout deliverables

When these functions are handled by separate parties, gaps appear. When they are handled as a Complete Spectrum of Field Services, the work is more predictable, and the project is easier to manage.

The Jobsite Is Dynamic, So the Support Has to Be Too

Industrial sites are rarely static. One day, access is open and material staging is simple. The next day, another trade is occupying the same corridor, a delivery arrives late, or a tie-in window gets shortened. A Complete Spectrum of Field Services is built for that reality.

Instead of treating the field as “install only,” a complete approach emphasizes:

- Field-driven constructability feedback

- Rapid response to constraints and interferences

- Tight alignment between the workface and fabrication or procurement updates

- Clear communication loops that reduce downtime

This is how field services become a project control tool, not just a labor line item.

Mobilization That Starts With Planning, Not Panic

A strong mobilization is one of the simplest ways to protect schedule and safety. Before a single weld is made, the team should understand access routes, laydown areas, permitting requirements, site orientation rules, and how work will be released.

With a Complete Spectrum of Field Services, mobilization includes:

- Work packaging aligned to the construction schedule

- Crew sizing based on realistic production goals

- Tooling and equipment planning to reduce “waiting on gear” delays

- Material staging and identification to keep installers building, not searching

This front-end structure reduces churn in the first two weeks of a project, which is often where timelines start to bend.

Skilled Craft Execution Across the Scope

Field services have to match the complexity of modern industrial work. Projects often involve a mix of stainless and high-alloy systems, tight tolerances, cleanliness requirements, or challenging access constraints. A Complete Spectrum of Field Services means the crew capability is broad enough to execute without constantly swapping subcontractors.

That can include:

- Pipe installation, fit-up, supports, and tie-ins

- Mechanical setting, alignment support, and connections

- Coordination with other disciplines to prevent rework

- Field measurements and as-built updates when conditions differ from drawings

The goal is to keep productivity steady even when the job throws curveballs.

Field Supervision That Connects the Dots

Great field work needs more than great welders and fitters. It needs supervision that can coordinate daily priorities, remove blockers, and keep the crew aligned with what matters most.

A Complete Spectrum of Field Services includes leadership that focuses on:

- Daily planning and constraint removal

- Interface coordination with other contractors and client reps

- Progress tracking tied to the schedule, not just hours worked

- Rapid escalation when RFIs, approvals, or material issues appear

This is where field services directly protect schedule performance.

Safety as a Built-In System, not a Binder on a Shelf

Industrial projects are high hazard environments. That is not a slogan, it is a reality reflected across construction risks like falls, struck-by hazards, electrical exposure, and equipment movement. OSHA provides step-by-step recommended practices for building effective safety and health programs, emphasizing management leadership, worker participation, and hazard identification and control as core elements.

A Complete Spectrum of Field Services treats safety as a daily operating system:

- Pre-task planning and job hazard analysis routines

- Clear communication on site-specific rules and expectations

- Competent-person coverage where required

- Strong housekeeping and access control to reduce secondary incidents

- Stop-work empowerment when conditions change

NIOSH also highlights the construction industry’s injury and fatality risks and the importance of resources that prevent work-related harm. When field teams are supported with consistent safety leadership, the job is not only safer, it is also more efficient because disruptions drop.

Quality Control and Documentation That Travel with the Work

Owners and EPC teams do not just buy installed piping. They buy traceability, inspection records, and confidence that the system will perform. A Complete Spectrum of Field Services includes QA processes that are aligned with the project’s inspection plan and turnover requirements.

That typically involves:

- Inspection hold-point coordination

- Weld documentation support and field record management

- Punch-list control and corrective action tracking

- As-built verification and closeout package support

When documentation trails behind installation, turnover gets delayed. When documentation is integrated into the field process, commissioning stays on pace.

Testing, Turnover, and Closeout Support

The last 10 percent of a project is where timelines often collapse. Testing, punch items, owner training, and turnover documentation can stall handover even when installation is finished.

A Complete Spectrum of Field Services includes support for:

- System readiness checks and pre-test walkdowns

- Test coordination and corrective work execution

- Commissioning support and rapid response to punch items

- Turnover package organization so the owner can operate and maintain confidently

This is where field services move from “construction” to “delivery.”

Why Integrated Field Services Reduce Cost and Risk

A Complete Spectrum of Field Services reduces project risk in practical ways:

- Fewer handoffs means fewer gaps in responsibility

- Better planning reduces idle time and rework

- Strong supervision improves workface readiness

- Embedded safety reduces incidents and disruption

- Tight QA control speeds turnover and acceptance

For industrial owners, it also means a more predictable experience. For EPC teams, it means fewer coordination burdens. For Ansgar, it is the standard for how field execution should be delivered.

Closing Thoughts

Industrial projects are won and lost in the field. Schedules, budgets, and quality outcomes depend on how well the jobsite is supported from mobilization through turnover. A Complete Spectrum of Field Services gives project teams the structure, capability, and leadership needed to execute safely and consistently, even when conditions change.

If your next project demands tighter coordination, higher quality consistency, and fewer execution surprises, Ansgar’s Complete Spectrum of Field Services approach is built to support industrial teams from the first day on site to final acceptance.